Experimental Study of the Impact of Various Bio Based Cutting Fluid Using Multiple Machining Characteristics during Shaping Operation

Keywords:

Tool, Work Specimen, Cutting Fluid, Machining Parameters, Surface Roughness.Abstract

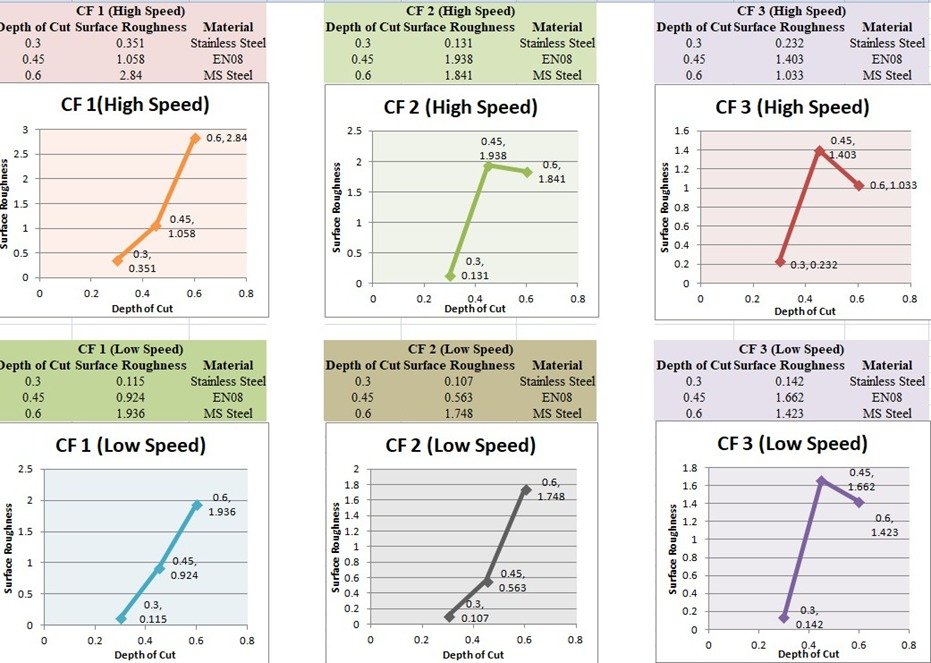

In machining, the use of cutting fluids in metal machining has several benefits, including increased tool life, less thermal deformation of the work piece, improved surface smoothness, and flushing away of chips from the cutting zone. - Three distinct vegetablebased cutting fluids, such as rice bran oil, almond oil, and sunflower oil, were used in this study to measure the surface roughness during shaping operations. Mild steel, stainless steel, and EN 8. Vegetable cutting oils have been studied for their potential to enhance surface finish during shaping at various speeds and feed rates. Speed, feed rate, and depth were taken into account as machining parameters in the trials. Cutting fluids; cutting fluids made from vegetables. Feed rate, speed, and depth of cut are all different cutting characteristics that are taken into account. Experimental research into surface roughness values is done after the three components are machined using various settings.

Published

How to Cite

Issue

Section

Copyright (c) 2022 Authors

This work is licensed under a Creative Commons Attribution 4.0 International License.