Design and Development of Combined Mechanical and Pneumatic Valve Spring Remover

Keywords:

: Combined Valve Spring Remover, Prototype, Engine Yamz-238, and Pressure Piece.Abstract

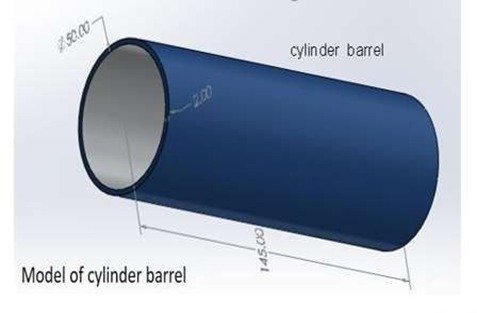

A combined mechanical and pneumatic valve spring remover is used to remove or install valve springs from an engine while the cylinder head is mounted on the engine or supported on a workbench (off the head). The designed tool was adjustable and mounted over the cylinder head by a stud. It can operate manually to depress the spring or by using an air compressor for a pneumatic actuator. The model of the tools is done by SOLIDWORK 2021 and we selected the stainless steel AISI grade-304(12) material. Tools were made following the calculations that have been done on valve springs. From the data calculation, the force required to depress the valve spring is 1350 N but the tools were designed to produce 1962.5 N by considering some friction loss. The analysis of the pneumatic system done by ANSYS software shows acceptable results like, Von Mises stress (20.036 MPa), maximum principal stress (26.426 MPa), and the total deformation becomes 1.6029×10-3. The prototype was built, and the test was carried out in time efficiently during the removal or installation of the valve spring on Engine YaMZ-238. The test result shows that to remove 4 springs, the designed tool is very effective to use by optimizing the difference in time savings of an average of 1 minute and 17 seconds when removing the spring valve, and 1 minute and 26 seconds when installing the valve, even when we use it mechanically. The developed valve spring remover has several advantages over the standard C-clamp tools, such as greater precision and accuracy in removing valve springs, reduced labor and time required for the task, and Increased safety with minimal human force.

Downloads

Published

How to Cite

Issue

Section

Copyright (c) 2024 Authors

This work is licensed under a Creative Commons Attribution 4.0 International License.